Waterford may be Ireland’s oldest city, but the first time I had heard of it was because of I saw its signature crystalware on a registry for a fancypants wedding. Seeing exactly what Waterford’s crystal-making tradition entails gives me new admiration for this handmade and quality craft.

Waterford City was chosen by founders George and William Penrose because of the abundant forest surrounding it. Lots of forest nearby means easily accessible fuel, a necessity to keep the factory’s kilns running.

Molds are still made from beech and pear woods for limited edition Waterford products, a rarity nowadays. Since Ireland doesn’t grow beech or pear, these woods are imported (yes that Waterford forest was basically all for the kilns). First the product is drawn on paper, the design is cut out, and the wooden mold is carved so the paper fits back inside the mold. One finished product can have multiple molds, particularly if it’s a complex shape.

Each mold is soaked in water for a day or two to before being used to hydrate it and help extend its life through the extreme temperatures it will face. Even so, a wooden mold will only last 7-10 days of use before needing to be replaced.

The glass is handled and shaped by Master Blowers and Craftsmen. It looks like a tiring job—and one that needs a large lung capacity and high tolerance to extreme heat.

It sits overnight in a special kiln in order to cool properly. It is then inspected with an eagle eye for bubbles (Waterford crystal is checked 6 times during production to ensure quality!). All crystal has bubbles, but if any are particularly large and/or take away from the beauty of the piece, the inspector will mark them. The cutter will then attempt to incorporate the bubbled area into the cut part of a pattern, but if this isn’t possible, the crystal will be destroyed and the remains will be sent back to the kiln to be reused.

Waterford takes much pride in the workmanship and hand-crafted quality of its product, so if it’s possible to do something by hand it’s definitely done by hand. An example of something that might not be done by hand would be a piece with lots of identically precise curves.

We got to interact with the cutters! I imagine there would be rules against disturbing folks working heavy (and potentially dangerous) machinery in The States. It’s wonderful to be in Ireland 😉

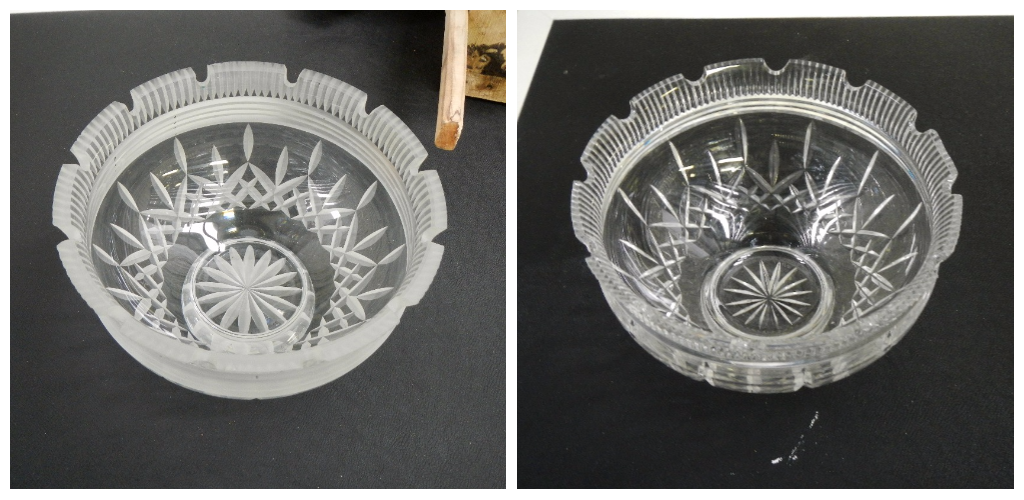

The Cutter below shows us the scalloped pattern he’s working on in the curves (compare to the uncut curves to the right/left of the one in the middle).

Once the piece is cut, it is given a mild acid bath overnight, to smooth out the cut edges and really make it sparkle.

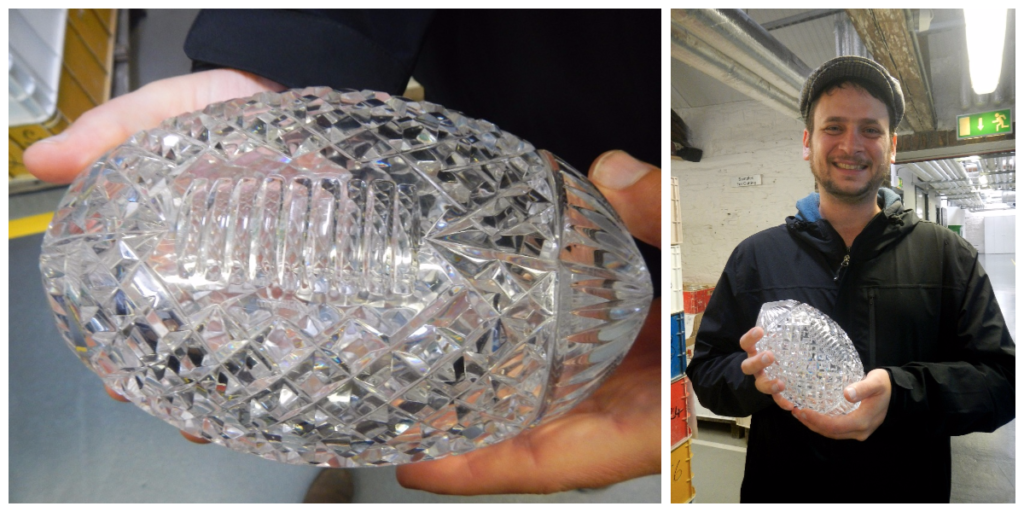

They actually let us hold many example pieces. They’re quite heavy! The one below was part of a football trophy of some sort. Since the custom molds for special-order products are already made, House of Waterford uses them as many times as possible.

We also went through a room where we saw artists at work sculpting, engraving, or preparing a crystal for etching. There are indeed many skills needed in fine crystal-making.

Of course, you exit the building after the tour through the gift shop, but the crystal art certainly deserves an audience, especially the one-of-a-kind pieces.

And some more fun Waterford-related facts:

- After a 5 year apprenticeship, an apprentice has a final test before becoming a master: to create a perfect Apprentice Bowl, a design which combines every cut used in wedge cutting.

- Everything vibrates (even if it’s imperceptible to us); if a sound/note is made at the same frequency as the crystal vibrates, it will shatter.

- The cracks in a crystal move at speeds of up to 4,800 km/hr.

- One of the ingredients in Waterford crystal is silica sand from Belgium which has an extremely high melting point and forms a clear and strong crystal.

- Red lead (from Holland) makes the crystal heavier and adds that sparkle and radiance which helps give Waterford crystal its trademark shine.

- A portable reheating furnace a crystal blower uses to make the crystal pliable is called a “Glory Hole.” It reaches temperatures of 1,300 C.

- “Vater Fjord,” as it was called, was pillaged, plundered, and then settled by Vikings who also introduced there Norse culture, red hair, and freckles to the isle.

After the tour they did not give samples like the chocolate factory. Humm, I say

Ps nice to know they keep their quality

That would be awesome if you got a sample!

I really liked this post, Sam. I have some crystal – I will have to look at it more closely and see exactly what it is.

Glad to hear it! Waterford’s crystal is beautiful–Let me know what you find!

Incredibly detailed care and beautiful. Didn’t know they were so meticulous in their processes!